When did you start building this robot, and how long did it take?

10/25/2025

The project took approximately three months to complete.

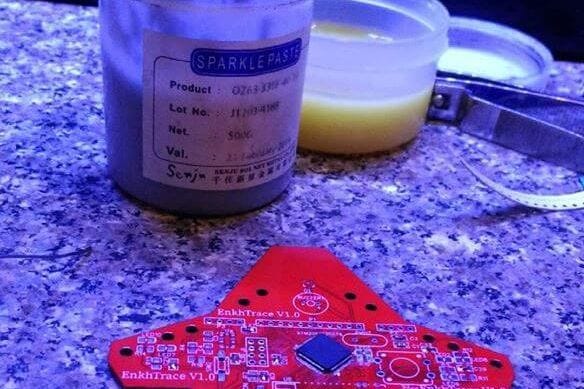

EnkhTrace Robot Soldering

What was the most challenging aspect you encountered?

The most challenging part was the line-following coding, which involved complex formulas, including PID control. On the technical side, the motor setup was particularly difficult, especially dealing with motor encoders and torque. The motor’s torque and speed are crucial for the performance of the line-following robot.

Enkhbold Ganbold EnkhTrace Line Follower PID

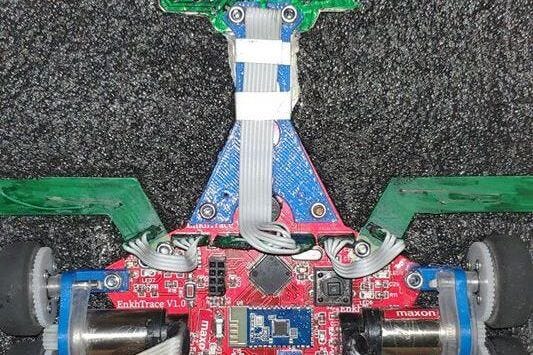

Robot Specifications:

Total Weight & Dimensions: 150g; 150cm x 151cm x 2.6cm

Maximum Speed: 3–4 m/s on a straight path

Battery: 7.4V 2S LiPo battery, 650mAh

Motor & Reduction System: Gear reduction ratio of 46:15 (3.06). The motor’s maximum speed is 14,800 RPM at 12V without gear reduction, which translates to 4,933 RPM with the reduction.

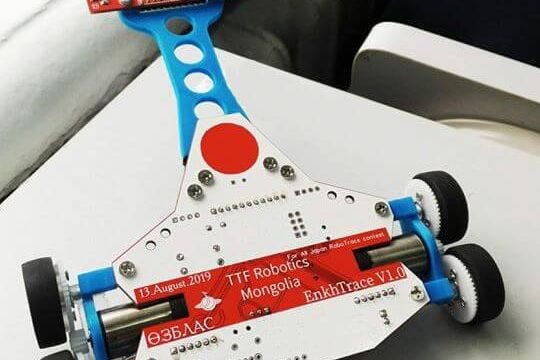

EnkhTrace Line Follower Robot first build

What is more important in your robot: torque or speed?

Speed is the more important factor for this robot.

Electronics Overview:

Microcontroller: STM32F103R8T6 MCU

Complementary Circuits:

5V 3A step-down buck regulator

TB6612 motor driver

QRE1113 IR sensor

LY3200ALH gyroscope

JDY30 Bluetooth module

Round buzzer

Untitled

PCB Manufacturing:

I designed and manufactured the PCBs using JLCPCB.

Sensors and Features:

Sensors Used: 10 IR sensors, 2 motor encoders, gyroscope sensor

Edge Sensor & Opponent Sensor Features: N/A

Competitions and Awards:

The robot won 2nd place twice in the National Robot Contest and 3rd place in the Robot Challenge Erdenet contest.

Future Plans for the Robot:

I plan to upgrade the robot with a camera for enhanced line-following capabilities.

Acknowledgment of JSumo Products:

I did once copy the design from the JSumo Storm line follower — what a learning experience!

General Part List:

MCU: STM32F103R8T6, 64MHz (with 8MHz external RC)

Motor Driver: TB6612FNG SMD

Motor: PORTESCAP 14,800 RPM at 12V, geared to 1:3, resulting in 4,933 RPM

Servo: MG90

Wheel Rubber: Paper load rubber from a printer

Sensor: QRE1113

Battery: LiPo 7.4V, 650mAh

Bluetooth Module: Bluetooth 5.0 JDY-30

SMD Resistor Sizes: 0402, 0603, 0805, 1206

Regulator: 5V 3A buck step-down

Motor Mount: 3D-printed or CNC

Gears: 46 teeth (on wheel), 15 teeth (on motor shaft)

Wheels: Acrylic, milled by CNC, with 8 bearings used on the wheels

EnkhTrace Line Follower Robot

Software Used:

SOLIDWORKS, EasyEDA, Keil, STM32CubeMX, Altium Designer, Autodesk Inventor

EnkhTrace Line Follower Robot

First Publish: https://blog.jsumo.com/enkhtrace-v1-3-ttf-robotics-mongolia/